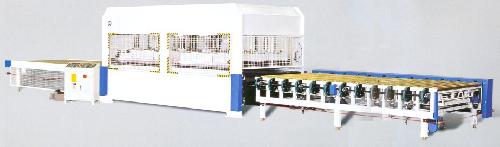

Interwood HOP 36/1600 through feed press

The Interwood HOP 36/1600 through feed press is a down stroke machine pressing platen, which operates from top to bottom.

The HOP 36/1600 was originally designed to make engineered flooring, but can now also be used for veneering chip board, MDF panels, laminate panels, bathroom panels, security doors and flush doors using heat to cure the adhesive.

The Interwood HOP 36/100 automatically feeds the panels in and out of the press, with the facility to off load sideways.

Heated Hydraulic veneer press technical information

- Worktable Dimension 3600 x 1600mm

- Platen Thickness 52mm Solid Steel

- Working Pressure 200T (3.5Kg/CM2)

- Main Cylinders 10 of 110mm

- Lift Cylinders 2 of 80mm

- Closing Speed 20-60mm/sec

- Heating Power 54kw

- Max Temperature 120.C

- Installed power 10kw

- Overall dimensions 11700 x 2300 x 2200mm

- Weight 12000kg

Worktable Dimension 3600 x 1600mm

Platen Thickness 52mm Solid Steel

Working Pressure 200T (3.5Kg/CM2)

Main Cylinders 10 of 110mm

Lift Cylinders 2 of 80mm

Closing Speed 20-60mm/sec

Heating Power 54kw

Max Temperature 120.C

Installed power 10kw

Overall dimensions 11700 x 2300 x 2200mm

Weight 12000kg